How PP Recycling is Shaping a Greener Tomorrow

How PP Recycling is Shaping a Greener Tomorrow

Blog Article

As sustainability becomes a key concentration global, the highlight is how industries may decrease environmental impacts. Polypropylene (PP), one of the very typically used parts, has received significant interest because potential in the circular economy. With rising concerns about plastic spend, PP recycle alternatives are emerging as a promising avenue for achieving sustainability objectives and lowering environmental footprints.

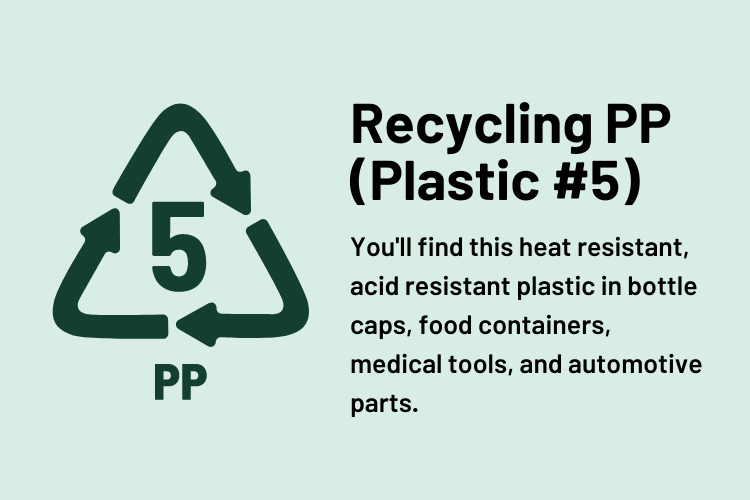

Polypropylene is popular across different industries, from packaging to automotive areas, because usefulness, strength, and cost-effectiveness. However, the persistence of PP in landfills and oceans creates a significant environmental challenge. Fortunately, developments in recycling systems are providing new options to sell PP more effectively and effectively.

One of the very most significant developments in PP recycling may be the escalation in mechanical recycling processes. Mechanical recycling involves breaking down plastic waste in to small particles, which can then be reprocessed into new products. This approach provides a more energy-efficient substitute compared to conventional plastic production. PP could be recycled multiple occasions, lowering the requirement for virgin material extraction and reducing the general carbon footprint.

Along with mechanical recycling, substance recycling technologies are developing traction. Chemical recycling involves wearing down pockets to their bottom chemicals, which is often reused to generate new plastic products. This technique permits the recycling of contaminated or mixed plastic waste that will usually be non-recyclable through old-fashioned methods. As substance recycling systems increase, they could revolutionize just how PP is refined and recycled, which makes it an integral player in the continuing future of plastic spend management.

The raising concentrate on PP recycling can be operating improvements in solution design. Businesses are developing PP services and products which are simpler to recycle by using monomaterial packaging, eliminating hazardous ingredients, and marketing styles that aid the recycling process. Venture across industries is vital to ensuring that PP products are recyclable from the start and may be successfully prepared by the end of these life cycle.

More over, client consciousness and behavior enjoy an important role in the success of PP recycling. With rising need for sustainable products and services, more people and organizations are taking steps to ensure PP waste is removed correctly. Education campaigns and incentive programs can encourage better recycling methods and support close the loop on PP waste.

Seeking forward, PP recycling solutions are positioned to be at the front of sustainable waste management. As technologies improve and industries embrace more round methods, PP can remain a valuable source, operating both environmental and financial benefits. The ongoing future of sustainability hinges on innovations in recycling, and PP recycling answers will truly enjoy a essential role in shaping that future. Report this page